Reyes Machinery

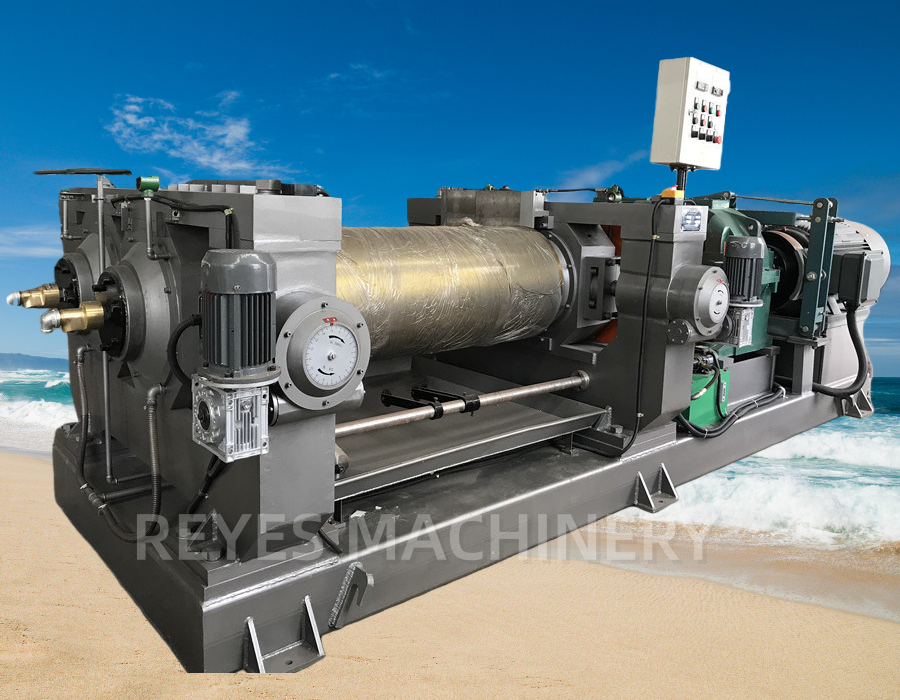

Reyes Machinery24Inch X(S)K610

Rubber Two Roll Mixing Mill

Double Motors,

Double Output with Hydraulic Board ,

Automatic Gap Control and Stock Blender

Rubber mixing mills offer several advantages over older models:

Applications of Rubber Mixing Mills –Rubber mixing mills are used in most industries requiring custom rubber compounds. Some of the major applications are as follows:

• Automotive: Tires, belts, hoses, and gaskets require special rubber mixes to resist wear and extreme conditions.

• Construction: Weather-resistant materials for windows, doors, and roofing products rely on rubber compounds.

• Footwear: The soles and heels of shoes use rubber compounds for durability and comfort.

• Industrial Products: In rubber manufacturing, seals, gaskets, and rollers require certain types of rubber for longevity and performance.

• Widely used in plastic processing and paint and pigment industrial production.

• Recycling and processing of waste rubber materials.

• Crushing, mixing and pressing of recycled rubber.

|

Roller diameter |

610mm (24 inch) |

|

Roller working length |

2000 mm |

|

Front roller speed |

28.4m/min |

|

Rear roller speed |

30m/min m/min |

|

Speed ratio |

1:1.2 |

|

Max.roll space |

15mm |

|

Once feeding capacity |

≤140kgs |

|

Main motor power |

160 kw |

|

Power supply |

380V-50Hz-3Phase |

|

Pressure of cooling water |

0.3 Mpa |

|

Bush |

Bearing type |

|

Emergency Stop |

Press Button Brake & Foot Brake |

|

Distance adjustment method |

Manual spacing adjustment |

|

Dimension |

7100X2530X1650 mm |

|

Weight |

41000kgs |

Have Any Questions !