Reyes Machinery

Reyes Machinery

Product Description

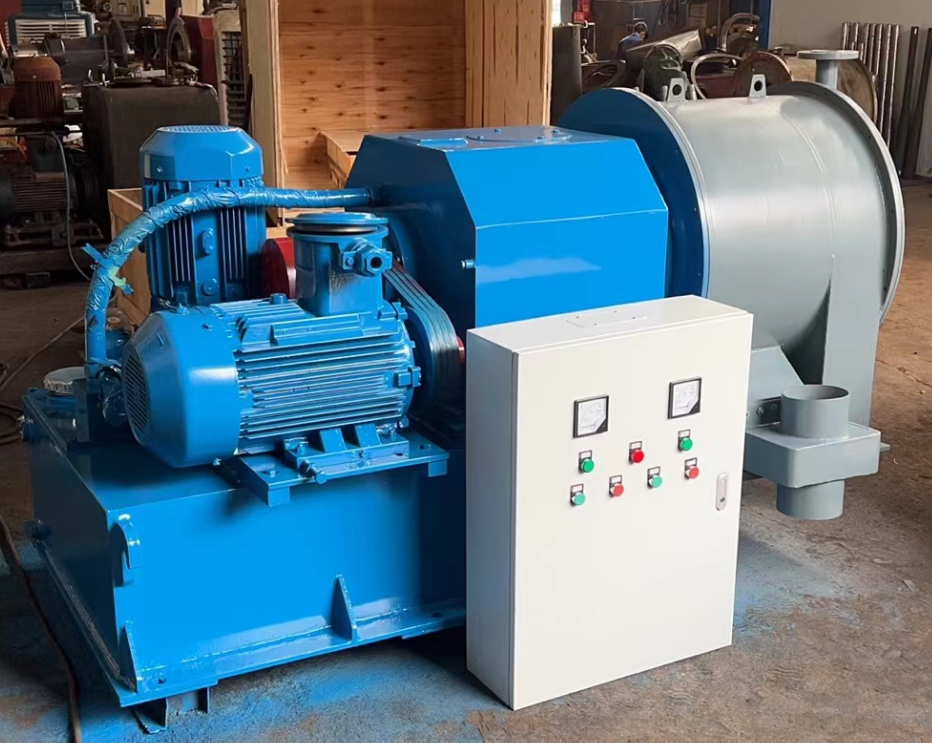

HR series industrial centrifuge of Two-stage piston pusher centrifuge is a continuous operation of the filter –type centrifuge. At full speed to comlete all of the operations processes :feeding, separation,washing,drying and unloding ,ect. Applied to the particles containing crystalline or short fibrous concentrated suspensions such as separation,widely used in chemical industry, salt pharmaceuticals, light industry and food industry, especially suitable for separation of solid phase material with particle size greater than 0.08mm,the concentration of more than 40% of the contained crystals or fibrous solids suspension of dehydration and solid-liquid speartion.

Applied Materials range: sodium chloride,ammonium chloride, potassium chloride,sodium sulfate ammonium sulfate,potassium sulfate,urea,potassium carbonate,PVC ,phosphate, nitrocellulose, cellulose acetate and so on.

Features:

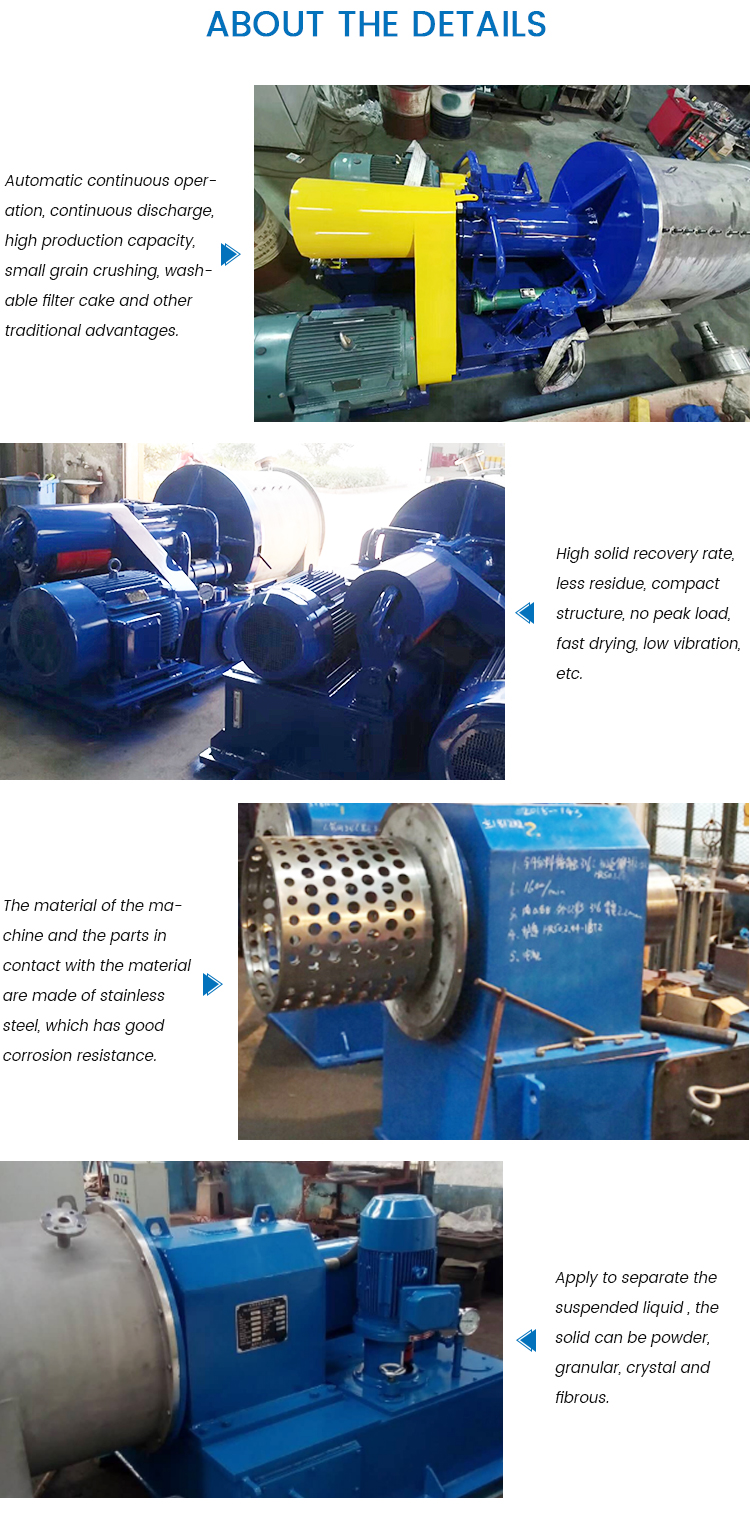

1. Continuous operation, large production capacity and stable operation.

2. The separation factor is high, the material can be fully dehydrated in the primary and secondary drums, and the moisture content of the filter cake is very low.

3. When the purity of the solid product is required, it can be effectively washed, and the washing liquid and mother liquor can be discharged separately.

4. Low power consumption.

Technical parameter of HR two-stage piston pusher centrifuge

|

HR Industrial Centrifuge Two-stage piston pusher centrifuge |

|||||

|

Model : |

HR300 |

HR400 |

HR500 |

HR630 |

HR 800 |

|

Bowl inside diameter(mm) |

218/262 |

337/400 |

438/500 |

560/630 |

720/800 |

|

Bowl length(mm) |

115/115 |

145/155 |

180/180 |

240/240 |

300/300 |

|

Bowl rotation speed(r/min) |

2200 |

1500-2500 |

1200-2000 |

1000-1800 |

800-1600 |

|

Determined according to the use requirements |

|||||

|

Separation factor |

710 |

573-1083 |

402-1120 |

350-1142 |

268-1145 |

|

Pushing stroke |

30-80 time/min |

30-80 time/min |

30-80 time/min |

30-80 time/min |

30-80 time/min |

|

Feeding capacity per hour |

1-3t/h |

1-8t/h |

5-15t/h |

8-25t/h |

25-65t/h |

|

Main motor power(kw) |

5.5 |

11 |

45 |

55 |

55-75 |

|

Auxiliary motor power |

3KW |

5.5 KW |

22KW |

30KW |

37KW |

|

Outline dimension(mm) |

1550*800*710 |

2460*1286*1180 |

3600*1420 *1200 |

3690*1600*1265 |

3700*1800*1450 |

|

Machine weight (kg) |

2000kg |

2480kg |

3500kg |

4100kg |

7000kg |

Have Any Questions !