Reyes Machinery

Reyes Machinery

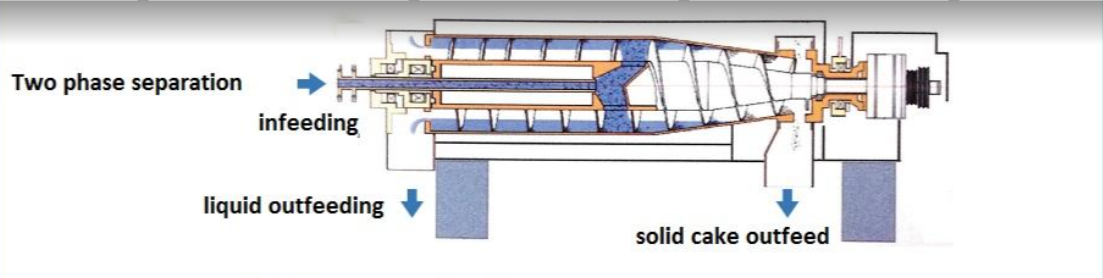

High speed decanter centrifugal separator centrifuge machine

Introduction

Centrifuge for continuous separation of solids from liquids such as thickening and dewatering sludge, suspensions with granular solids, clarification of liquids, separating Calcium citrate,Quartz stone powder etc. We provide a broad range of DECANTER sizes.

Application

Structure

The drum and the spiral feeder rotate in the same direction but with a certain speed difference; the material is led into the feeding spiral inner cylinder via the feeding pipe and, after speeding pipe and, after speeding up, enters the drum; under the action of the centrifugal force field, the relatively heavier solid-phase material deposits on the drum wall forming the residue layer; the solid-phase residue is continuously pushed by the spiral feeder to the conic end of the drum and, after dehydration in the drying area, is discharged out of the machine. The machine is capable of continuous feeding, separating, dehydrating and discharging under full-speed running.

Feature

Technical Parameter

|

Model |

Diameter (mm) |

Length (mm) |

Max speed |

L/D ratio |

G- force |

Capacity (m3/h) |

Main motor power (Kw) |

Weight (kg) |

Dimension (mm) |

|

LW250*1000 |

250 |

1000 |

5000 |

4 |

2722 |

0.5-5 |

7.5 |

1600 |

2120*1250*680 |

|

LW300*1200 |

300 |

1200 |

4000 |

4 |

2784 |

2-6 |

11 |

2700 |

2450*1300*900 |

|

LW355*1460 |

355 |

1460 |

3600 |

4 |

2576 |

2-10 |

15 |

2850 |

2750*1350*830 |

|

LW400*1200 |

400 |

1200 |

3200 |

3 |

2294 |

3-12 |

18.5 |

3100 |

2730*1600*1080 |

|

LW400*1600 |

400 |

1600 |

3000 |

4 |

2016 |

3-15 |

22 |

3260 |

3130*1600*1080 |

|

LW450*1800 |

450 |

1800 |

2800 |

4 |

1976 |

4-25 |

37 |

3250 |

3320*1700*1130 |

|

LW500*2000 |

500 |

2000 |

2500 |

4 |

1750 |

5-35 |

45 |

4000 |

3520*1800*1170 |

|

LW530*2120 |

530 |

2120 |

2400 |

4 |

1709 |

5-40 |

55 |

4800 |

4150*1350*1600 |

|

LW550*2200 |

550 |

2200 |

2800 |

4 |

2415 |

6-40 |

55 |

5700 |

4570*1380*1600 |

|

LW650*1950 |

650 |

1950 |

2200 |

3 |

1761 |

6-45 |

75 |

5000 |

4840*1510*1720 |

|

LW650*2600 |

650 |

2600 |

2000 |

4 |

1456 |

6-65 |

90 |

6000 |

5490-1510*1720 |

|

LW720*2160 |

720 |

2160 |

2000 |

3 |

1612 |

7-80 |

120 |

6000 |

5200*1600*1800 |

|

LW720*2880 |

720 |

2880 |

2000 |

4 |

1306 |

7-90 |

120 |

8000 |

3100*1600*1800 |

|

LW800*2400 |

800 |

2400 |

1800 |

3 |

1451 |

20-120 |

150 |

12000 |

5820*2000*1300 |

|

LW800*3200 |

800 |

3200 |

1800 |

4 |

1451 |

20-120 |

150 |

13000 |

7100*2000*1300 |

Have Any Questions !